+86 133 0307 8975

+86 133 0307 8975

Dec. 31, 2025

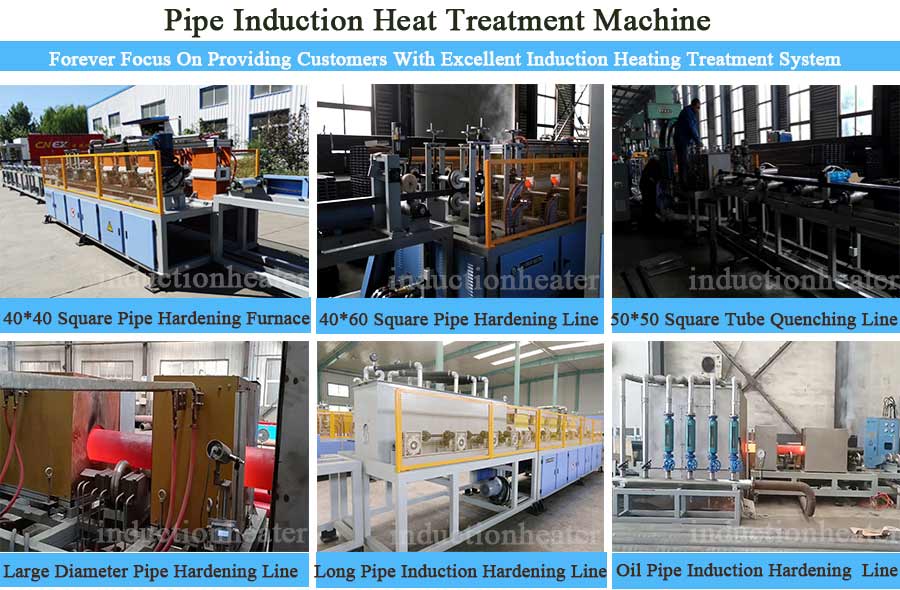

The Forever square steel pipe induction hardening and tempering furnace is widely used in the heat treatment field of metal pipes such as petroleum casing and square tubes. Its core advantages lie in energy saving, consumption reduction, and process stability.

1、 Technical advantages

Energy conservation and consumption reduction: The power consumption per ton is controlled between 450-500 kWh, significantly reducing production costs.

Efficient heating: pipe induction heat treatment machine using intermediate frequency or high-power series power supply, quickly heating to the critical temperature (850-950 ℃), multi zone sensors are segmented and independently regulated to ensure uniform heat transfer throughout the entire length of the steel pipe.

Precise temperature control: Closed loop control is achieved through PLC and infrared temperature measurement, with a tempering temperature range of 450-650 ℃ and high temperature control accuracy.

2、 Equipment composition and functions

Power supply and heating system: Adopting intermediate frequency or high-power series power supply, quickly heating to the critical temperature (850-950 ℃), multi zone sensors are segmented and independently regulated to ensure uniform heat transfer throughout the entire length of the steel pipe.

Conveying and rotating device: The roller conveyor is made of stainless steel or alloy steel material, which has high temperature resistance and corrosion resistance. The inclination angle is designed between 18-21 ° to ensure that the steel pipe rotates and heats up during the conveying process.

Quenching cooling system: The cooling ring is arranged in sections, and the water flow and pressure can be independently controlled to avoid uneven cooling. It is equipped with water quality filtration and automatic water replenishment system to reduce the risk of blockage and scaling.

Tempering heating unit: using induction tempering with a temperature range of 450-650 ℃, closed-loop control is achieved through PLC and infrared temperature measurement, resulting in higher efficiency and better temperature control accuracy.

Control and detection system: The centralized control cabinet integrates power, temperature, and water pressure monitoring, and is equipped with a process database that can quickly switch heat treatment parameters of different steel grades. Some solutions are equipped with energy consumption analysis modules to help users optimize production costs.

The production process of square steel pipe induction hardening and tempering machine does not produce harmful substances, effectively improving the working environment of workers. By using induction frequency to quench the square tube, the yield rate is high and it is more energy-efficient.

If you are also interested in this machine,please don't hesitate to contact us:

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone/Wechat/Whatsapp:+86 13303078975

Navigation

Tel.:+86 133 0307 8975

E-mail: tom@foreverfurnace.com

WhatsApp: +86 133 0307 8975

Add.: Wuqiao Economic Development Zone, Hebei Province, China, Cangzhou, Hebei, China

FOLLOW US